Research and Development

Every production reality has unique characteristics, both in terms of space constraints and potential dangers for people and the environment, and we know this well. Relying on the experience and expertise of the engineering department Sall means choosing for your company the certainty of using the most effective solutions, easy to use, safe and that comply with current standards and regulations. Sall has always created the best handling and storage solutions for maximum environmental and business safety around your needs.

The art of Design Meets Advanced Technology

“Design is the art of shaping safety of use and the best possible experience for the operator without having to sacrifice the aesthetics and durability of the equipment thanks to technology”

– Antonio Loiacono Engineering Manager

All Sall projects start from the detailed and careful analysis of the plant and the operating spaces of our customers. This in-situ consulting enables you to develop solutions around the real needs and security risks of your company.

The design phase is an extremely analytical and technical process that includes the study of materials, shapes and all those details that significantly contribute to ensuring the highest level of safety, simplification of operations and, consequently, the reduction of operating costs.

Prototyping

Your safety is our priority.

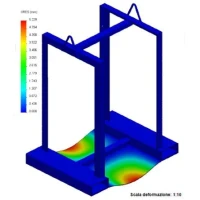

The high quality and effectiveness of all products is also guaranteed by structural tests, which are performed in Sall through the use of advanced software on virtual prototypes. Tests are also conducted on pre-production prototypes, in order to test their real performance.

Structural, Stress and Usage Tests

All products are subjected to rigorous structural, usage and stress tests that allow further verification of compliance with the strict Sall quality standards, strength, effectiveness and safety of use.

Quality and Compliance with Regulations and Standards.

- Complete tracking of raw materials.

- Production process certification according to UNI EN ISO 9001:2015.

- Welding quality certification according to UNI EN ISO 3834-2:2021.

- Experienced and certified staff for non-destructive testings, compliant with UNI EN ISO 9712:2012.

- Certification for testing with hazardous liquids to verify product water-tightness UNI EN ISO 3452-1:2013.

- Certification for visual inspection UNI EN 13018:2016.

- Certification for non-destructive verification of welding quality, in compliance with UNI EN ISO 23277:2015.

- Certification for the quality levels of imperfection of welded joints UNI EN ISO 5817:2014.

- UNI EN 1090-2:2018.

- NTC 2008.

- EN 13501-2:2016 procedure for the classification of products and elements used in constructions for fire and smoke resistance, according to the field of application and method used.

- UNI EN ISO 12944: standard for coating corrosion resistance.

Need Technical Advice for Your Project?

Just fill in this form and request the free engineering consulting service!